In 2003 there was an adaptation to ISO 9001:2000(Vision 2000) standards regarding the quality of the internal procedures.

In 2005 the certification was extended also to the planning phase and dimensioning of the heat exchangers.

Another important step was the attainment, in 2012, of the qualification of the welders and the brazers in compliance with what is prescribed in the UNI EN ISO 13585:2012 and 13134 regulations.

The production of the heat exchangers is carried out according to the European PED – Pressure Equipment Directive – concerning the pressurized containers which allow the circulation of the products all over Europe. So we are able to supply heat exchanger products in compliance with the IV PED category which requires higher quality fulfillments by the manufacturers.

In May 2015 Calligaris Srl obtained approval for the construction of pressure equipment to design and build pressure equipment - BPV - compliant with ASME Boiler Pressure Vessel Code Sect. VIII Div. 1 marked "U-stamp" and that can be registered with the National Board.

The company quality system has transposed the most stringent demands of the ASME Code as regards design, management of purchasing specifications and construction procedures of pressure equipment.

Calligaris can weld and solder in accordance with the requirements of Section IX of the ASME Code.

The weldings carried out can be tested internally with non-destructive tests such as penetrating liquids according to UNI EN ISO 9712:2012 and to the Recommended Practice SNT-TC-1A-2006.

TESTING

According to the customer’s needs, the heat exchangers may be tested at a higher pressure in compliance with what is required by law.

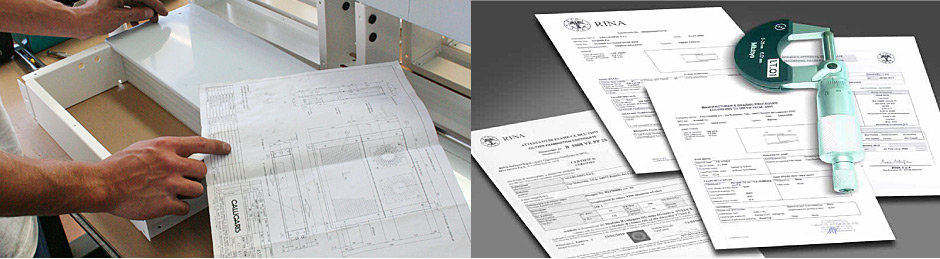

A dimensional control on the products is also made to guarantee compliance with the architectural designs.

- pneumatic testing up to 35 bar

- hydrostatic testing

- electrical component testing