Customized products

Customized Solutions

We use three-dimensional drawing programmes that allow a rapid exchange with our customers in order to verify the compatibility of the designed component. We also perform fatigue calculations to ensure the durability of specific products and structural calculations according to EN 13445 or ASME VIII.

Geometries

Varnishing Treatments

Carpentry

Made according to the chosen materialGeometries

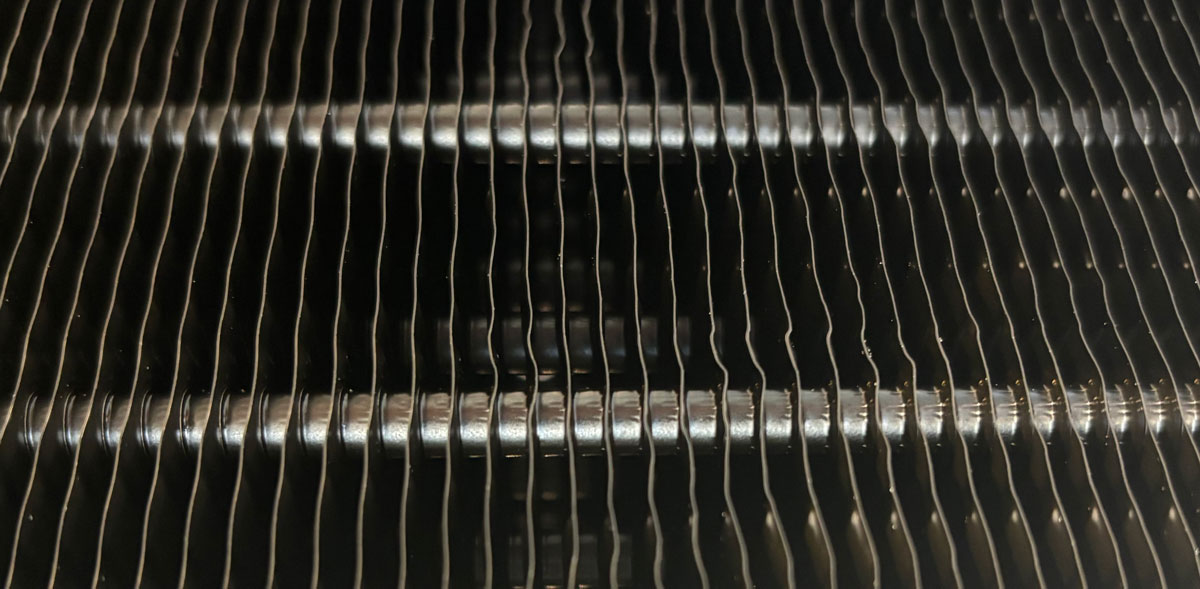

One of the fundamental components for the exchangers is the geometry that is used to maximize the thermal flux between the two fluids; in fact, the tube diameter is chosen according to the application of the exchanger, the material from which the fins are made and their geometry.

ø7 - 25X21,65

| Features | Tube outer diameter (mm) | 7 |

| Minimum fin pitch (mm) | 1,6 | |

| Maximum fin pitch (mm) | 5 | |

| Fins | Aluminum (mm) | 0,10 / 0,12 / 0,15 / 0,18 |

| Hydrophilic aluminum (mm) | 0,10 / 0,12 | |

| Copper (mm) | 0,10 / 0,12 | |

| Tubes | Copper (mm) | 0,27 |

| Copper helically toothed (mm) | 0,27+0,18 | |

| K65 (mm) | 0,42 |

ø9,52 - 25x12,5

| Features | Tube outer diameter (mm) | 9,52 |

| Minimum fin pitch (mm) | 1,6 | |

| Maximum fin pitch (mm) | 3,4 | |

| Fins | Aluminum (mm) | 0,12 / 0,18 |

| Hydrophilic aluminum (mm) | 0,12 | |

| Tubes | Copper (mm) | 0,28 / 0,30 / 0,35 / 0,41 |

| Copper helically toothed (mm) | 0,28+0,20 |

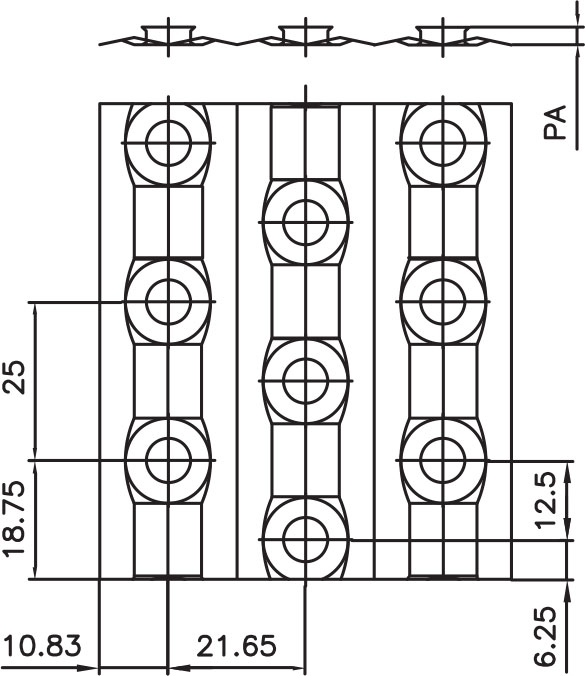

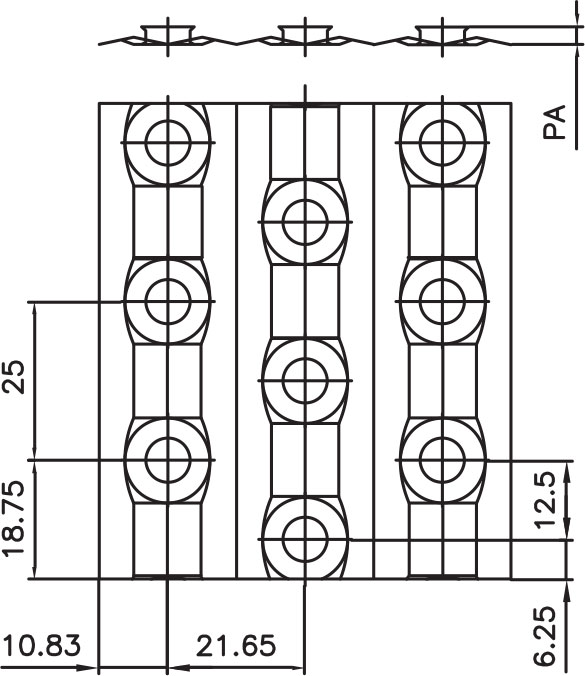

ø9,52 - 25x21,65

| Features | Tube outer diameter (mm) | 9,52 |

| Minimum fin pitch (mm) | 1,6 | |

| Maximum fin pitch (mm) | 6 | |

| Fins | Aluminum (mm) | 0,10 / 0,12 / 0,15 / 0,18 |

| Hydrophilic aluminum (mm) | 0,10 / 0,12 | |

| Prepainted aluminum (mm) | 0,12 | |

| Copper (mm) | 0,10 / 0,12 | |

| Stainless steel AISI 316L (mm) | 0,125 | |

| Tubes | Copper (mm) | 0,28 / 0,30 / 0,35 / 0,41 / 0,70 / 0,90 |

| Copper helically toothed (mm) | 0,28+0,20 | |

| Cupronickel (mm) | 0,45 / 0,50 | |

| Stainless steel AISI 316L (mm) | 0,50 |

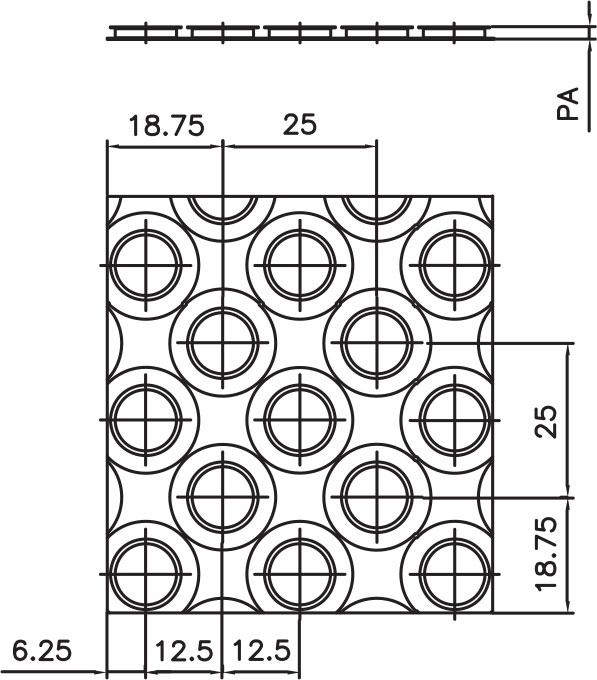

ø9,52 - 25x25

| Features | Tube outer diameter (mm) | 9,52 |

| Minimum fin pitch (mm) | 1,7 | |

| Maximum fin pitch (mm) | 5,5 | |

| Fins | Aluminum (mm) | 0,15 / 0,18 / 0,25 |

| Copper (mm) | 0,10 | |

| Tubes | Copper (mm) | 0,28 / 0,30 / 0,35 / 0,41 / 0,7 / 0,9 |

| Copper helically toothed (mm) | 0,28+0,20 | |

| Cupronickel (mm) | 0,45 / 0,50 | |

| Stainless steel AISI 316L (mm) | 0,50 |

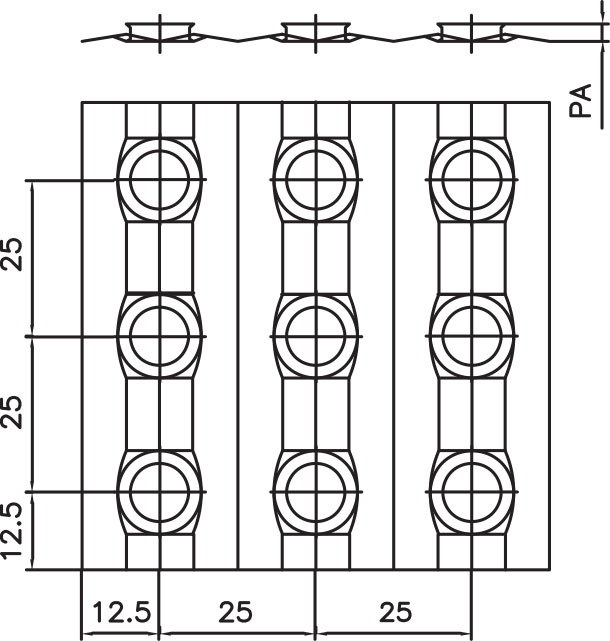

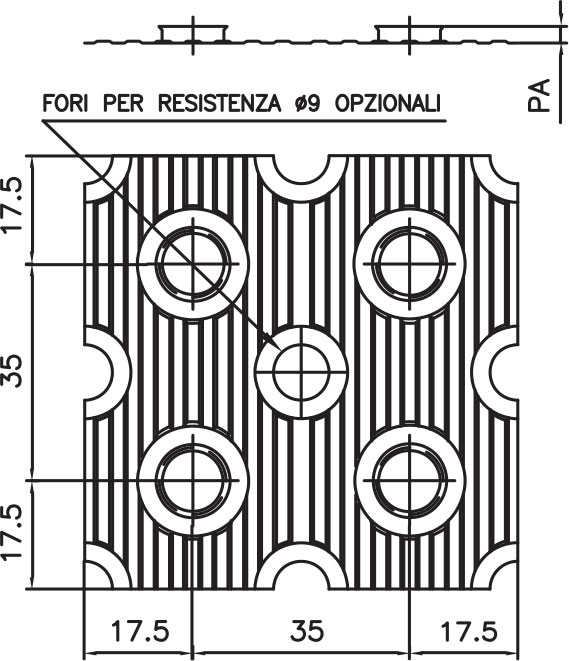

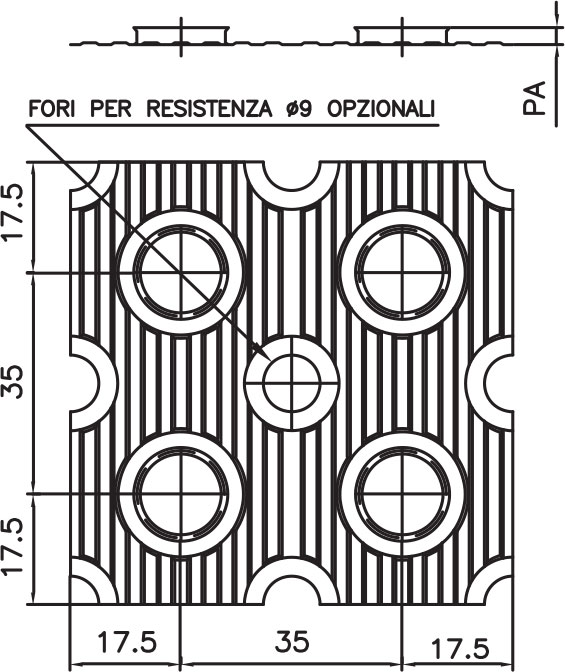

ø9,52 - 35x35

| Features | Tube outer diameter (mm) | 9,52 |

| Minimum fin pitch (mm) | 3,5 | |

| Maximum fin pitch (mm) | 10 | |

| Fins | Aluminum (mm) | 0,18 / 0,20 / 0,25 |

| Copper (mm) | 0,12 | |

| Tubes | Copper (mm) | 0,28 / 0,30 / 0,35 / 0,41 / 0,70 / 0,90 |

| Copper helically toothed (mm) | 0,28+0,20 | |

| Stainless steel AISI 316L (mm) | 0,50 |

ø12,7 - 35x35 e 35x70

| Features | Tube outer diameter (mm) | 12,7 |

| Minimum fin pitch (mm) | 2,5 | |

| Maximum fin pitch (mm) | 12 | |

| Fins | Aluminum (mm) | 0,18 / 0,20 / 0,25 |

| Tubes | Copper (mm) | 0,35 / 0,75 |

| Copper helically toothed (mm) | 0,36+0,25 |

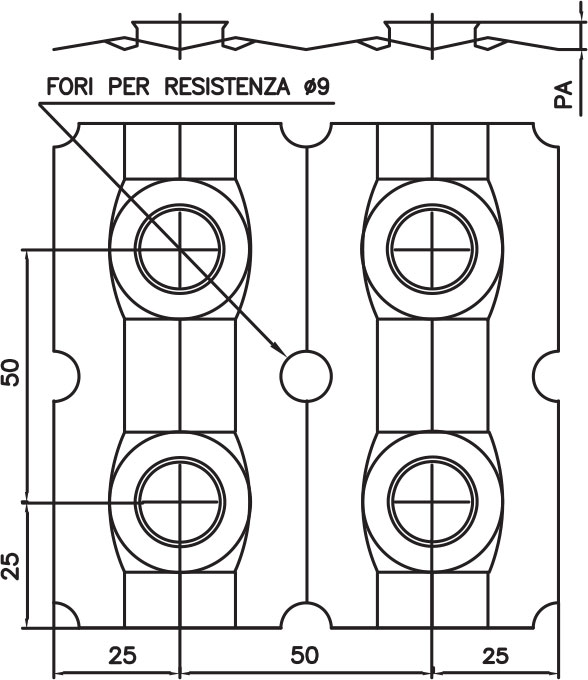

ø15,88 - 50x50

| Features | Tube outer diameter (mm) | 15,88 |

| Minimum fin pitch (mm) | 2,5 | |

| Maximum fin pitch (mm) | 10 | |

| Fins | Aluminum (mm) | 0,18 / 0,25 |

| Tubes | Copper (mm) | 0,38 |

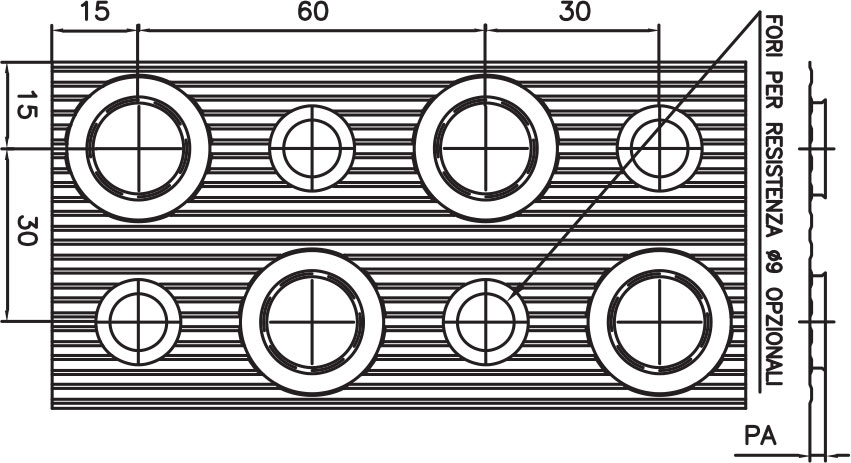

ø15,88 - 60x30

| Features | Tube outer diameter (mm) | 15,88 |

| Minimum fin pitch (mm) | 2,5 | |

| Maximum fin pitch (mm) | 8 | |

| Fins | Aluminum (mm) | 0,20 |

| Tubes | Copper (mm) | 0,38 |

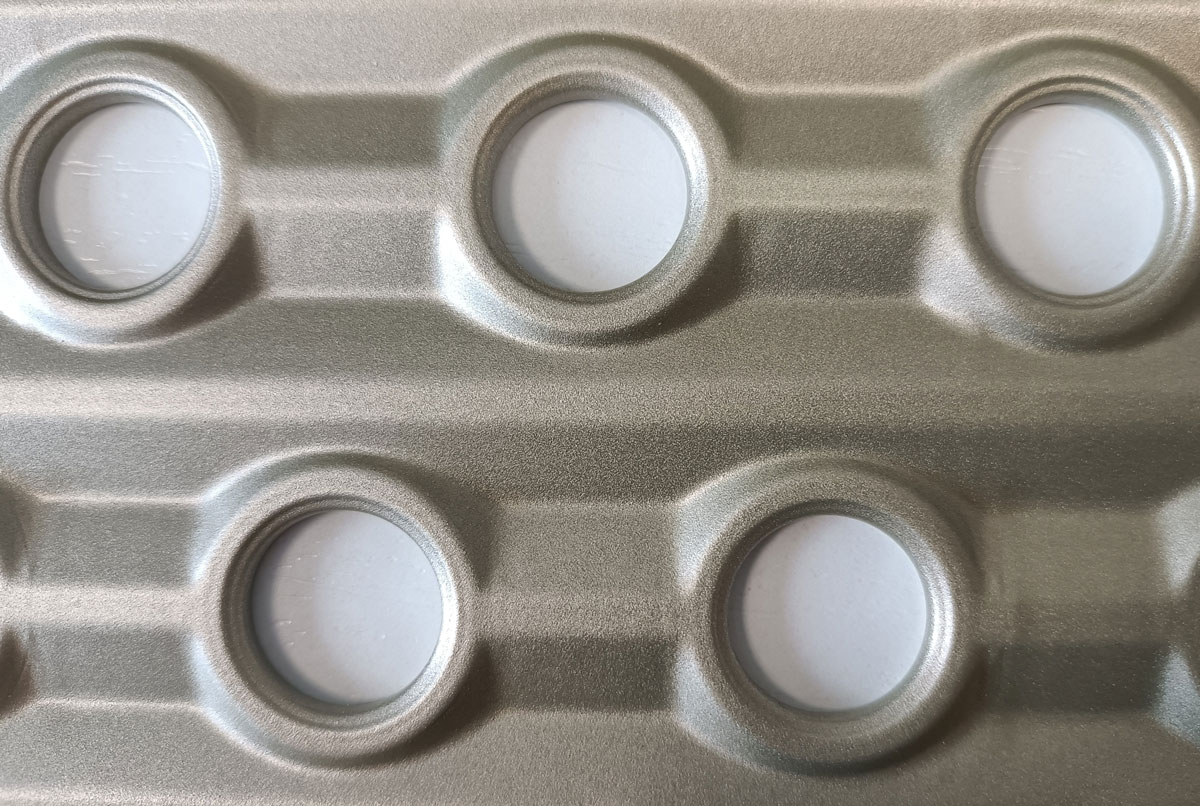

Treatment according to requirementsVarnishing Treatments

Blygold® PoluAl XT

This polyurethane coating with aluminium pigments protects the heat exchangers from a saline environment, chemicals (resistance chart available) and UV radiation. Corrosion resistance (ASTM B117): 4,000 hours. Colour: champagne.

Thermoguard Finguard Silver SB

This polyurethane coating with aluminium pigments protects the heat exchangers from a saline environment, chemicals (resistance chart available) and UV radiation. Corrosion resistance (ASTM B117): 3,000 hours. Colour: silver.

Heresite P413

Heresite® is a modified phenolic, thermosetting resin for corrosion protection in special applications. P413 offers high resistance in marine environments and against a wide variety of corrosive fumes. High resistance to low and high temperatures and FDA/NSF certification for indirect food contact make it a solution for a wide range of applications. Corrosion resistance (ASTM B117): 6,000 hours. Colour: dark brown.

Powder coating

Powder coating is a procedure for coating metal surfaces in all colour shades. Thanks to electrostatic painting, an even distribution of the paint and greater durability are achieved on any material. A wide range of RAL colours can be used.

Aqua Aero

Excellent corrosion resistance for the most aggressive marine and industrial environments. Aqua Aero’s water-based coatings are C5-rated (ISO 12944-6) and FDA-approved for the food industry. Aqua Aero offers different anti-corrosion solutions for all types of environments: – Smart Tier: 10,000 h ASMT B117 – Mid Tier: 15,000 h ASMT B117 – High Tier: 20,000 h ASMT B117 Standard RAL colours: RAL 9005, 5009, 5012 and 7001

Cataphoresis

Cataphoresis is an advanced surface treatment designed to give metal and other alloy elements extraordinary resistance to chemical and environmental corrosion. This process uses epoxy resins and guarantees a uniform coating. Applied by electroplating, it is particularly recommended as a primer coat for powder coating. Colour: black

Manufactured in various sizes and materialsCarpentry

Thanks to its accurate three-dimensional design and to modern punchers and numerical control bending machines, it is possible to make carpentry and structures of different sizes that can be adapted to any construction requirement of the customer.

Galvanized steel plates

| Thickness (MM) |

|---|

| 0,8mm / 1,2mm / 1,5mm / 2mm / 3mm |

Alluminium plates

| Type | Thickness (MM) |

|---|---|

| 1054A H24 | 1mm / 1,2mm / 1,5mm / 2mm / 3mm |

| 1054A H24 plated with protective pvc | 1mm / 1,2mm / 1,5mm |

| Aluminium magnesium 5754 | 0,8mm / 2mm / 3mm |

| Alluminium manganese 3105 H24 plated with protective pvc | 1,5mm |

Stainless steel plates

Aisi 304 / Aisi 316 plated with protective pvc

| Thickness (MM) |

|---|

| 0,8mm / 1,5mm / 2mm |

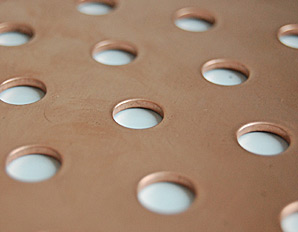

Copper plates

| Thickness (MM) |

|---|

| 1,5mm / 2mm |

Brass plates

| Thickness (MM) |

|---|

| 1,5mm |

Ad hoc solutions

Tailor-made products, customization and design collaboration with the customer, deliveries of even small batches

Experience and Innovation

Experience innovation and flexibility are the basis of Calligaris' business philosophy

Quality Supplies

Calligaris achieves a high standard of product quality and customer service