Several special procedures are available, from treatment of surfaces to TIG welding, that Calligaris provides to further customize the product.

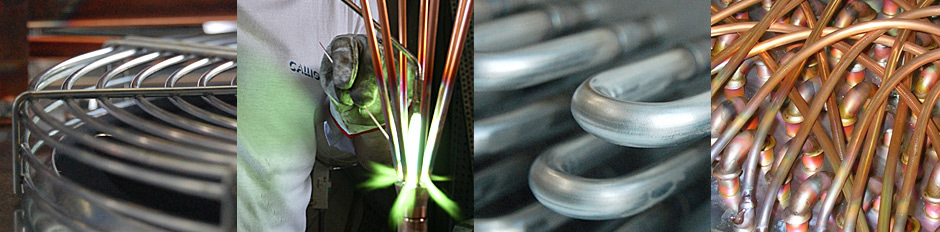

Welding

The welding of curves and connections is carried out with copper and phosphorous solder with some percentage of silver, welding takes place in a controlled atmosphere in order to avoid cases of oxidation on the internal surface of the tubes and to guarantee a clean circuit.

- brazing with different silver contents

- brazing

- welders and the process are certified

TIG Welding

To carry out TIG welding both regarding 9,52 mm circling in stainless steel and regarding manifolds and airtight welding in carpentry.

- TIG welding of stainless steel circling

- TIG welding of manifolds

- airtight carpentry welding

Surface Treatments

In some particular situations, it is necessary to carry out surface treatments in order to increase the resistance to corrosion of the entire exchanger, or in other cases it might be necessary to eliminate any oil residue present on the surfaces.

According to your application, we can advise you of the most appropriate treatment.

- electrophoresis

- painting with epoxy powder

- oxidation

- blygold

- galvanizing

- ultrasonic cleaning

Installation of fans and resistors

According to our customers’requirements, the exchangers can have accessories such as fans, the wiring of motors, the installation of resistors inside the finned unit, the assembly of millwork valves or the installation of anti-vibration supports.

In this way, the products fit easily into our customers’chain of production facilitating the assembly process.

- motors

- resistors

- wiring