One of the fundamental components for the exchangers is the geometry that is used to maximize the thermal flux between the two fluids; in fact, the tube diameter is chosen according to the application of the exchanger, the material from which the fins are made and their geometry.

THE FINS

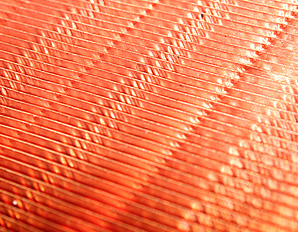

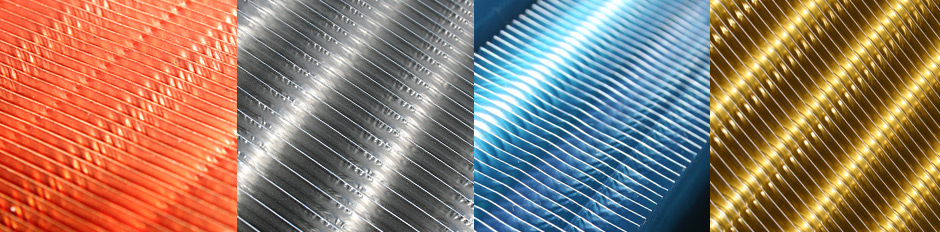

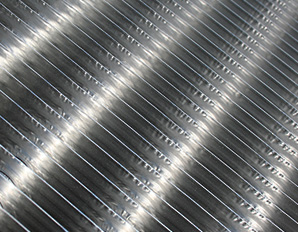

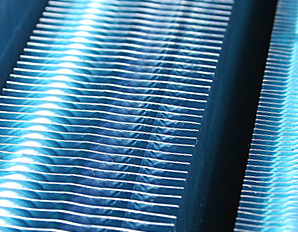

The fins, made of aluminium, prevarnished aluminium or copper, are pressed by means of a particular ondulation that increases the thermal exchange between the air and the fin reducing the load losses on the air side and encouraging at the same time the flow of condensation or defrosting water.

The fins can also be made from 316L stainless steel for installations where the thermal exchange is in aggressive environments such as the food sector or exchangers used in salty environments.

The main geometries, achievable according to the chosen material, are reported following below; besides, according to the application chosen by the customer and to the thickness of the requested strap, it will be possible to make a major or minor pitch between the fins.

DOWNLOAD

ALUMINIUM FINS

| Achievable geometry (mm) | Fin pitch (mm) |

|---|---|

|

25x12,5 |

1,6÷3,4 mm 1,6÷6 mm 1,7÷5,5 mm 2,5÷12 mm 2,5÷10 mm 2,5÷10 mm |

HYDROPHYLIC ALUMINIUM FINS

| Achievable geometry (mm) | Fin pitch (mm) |

|---|---|

| 25x12,5 25x21,65 |

1,6÷3,54 mm 1,6÷3,54 mm |

PREVARNISHED ALUMINIUM FINS

| Achievable geometry (mm) | Fin pitch (mm) |

|---|---|

| 25x21,65 | 2÷4,2 mm |

STEEL FINS 316L

| Achievable geometry (mm) | Fin pitch (mm) |

|---|---|

| 25x21,655 / 35x35 | 2,1÷3,6 mm |

COPPER FINS

| Achievable geometry (mm) | Fin pitch (mm) |

|---|---|

| 25x21,65 25x25 35x35 |

1,6÷4,8 mm 1,67÷3,5 mm 2,5÷4 mm |